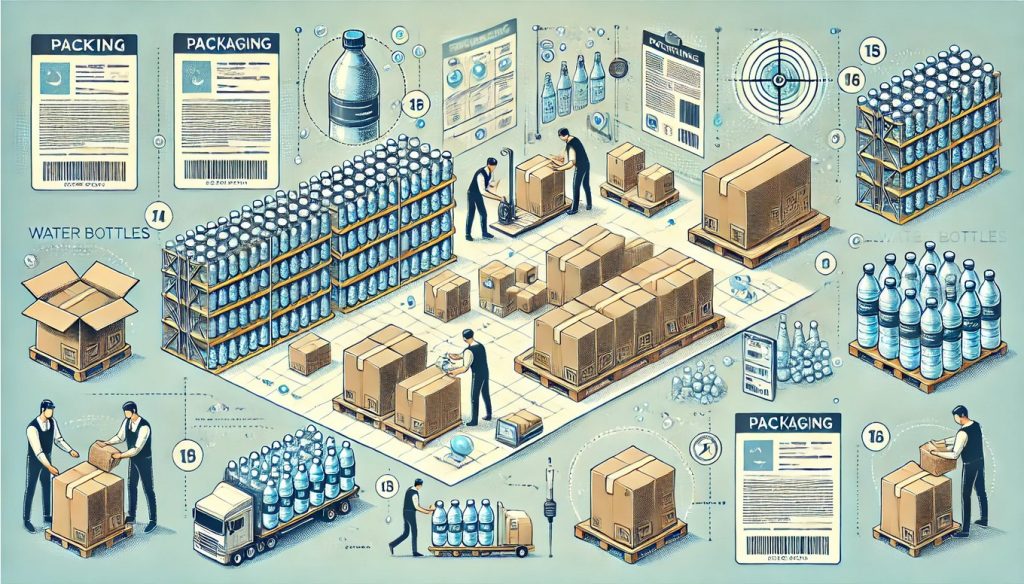

The Importance of Proper Packaging for Water Bottles in Wholesale Orders

The water bottle industry has seen significant growth in recent years, particularly in the wholesale sector, as demand for sustainable, reusable, and high-quality water bottles continues to rise. Whether you are a manufacturer, distributor, or retailer, effective packaging is essential when handling wholesale orders. Proper packaging not only ensures the protection and safe delivery of your products but also plays a critical role in branding, customer satisfaction, and operational efficiency.

When dealing with bulk orders, the importance of secure, cost-effective, and environmentally-friendly packaging becomes even more pronounced. With wholesale orders often involving large quantities of products, improper packaging can lead to product damage, increased shipping costs, and negative customer experiences. Additionally, as more consumers demand sustainability from the brands they purchase, packaging practices must reflect eco-conscious values.

Packaging Water Bottles for Protection During Transit

Choosing the Right Packaging Materials

One of the key priorities in packaging water bottles for wholesale orders is ensuring that the bottles are protected during transit. Water bottles, especially those made from glass or stainless steel, are prone to damage if not packed properly. Selecting the right packaging materials is essential to minimize the risk of breakage or dents during shipping.

Foam Inserts and Dividers

For bottles made of glass, ceramic, or thin-walled plastic, using foam inserts and dividers can help provide cushioning and support. Foam dividers are ideal for separating individual bottles, preventing them from clinking together or shifting inside the package. These dividers can be cut to fit the specific dimensions of your water bottles, ensuring that each bottle is securely held in place.

Eco-friendly foam alternatives, such as biodegradable foam or recycled materials, are a great choice for businesses that prioritize sustainability. These options still offer the same level of protection without compromising on environmental values.

Bubble Wrap or Air Pillows

For smaller orders or added protection, bubble wrap or air pillows can be used to encase individual bottles. Bubble wrap provides a soft, protective layer around each bottle, preventing scratches, cracks, or breakage. Similarly, air pillows, which are filled with air and sealed in plastic, can create a protective cushion around bottles without taking up too much space.

Corrugated cardboard tubes can also be used for shipping certain types of water bottles, such as those with large, wide bodies or special designs. These tubes provide a rigid, durable container that can protect bottles from impact during transit.

Proper Box Sizing

The size of the shipping box is just as important as the packing materials inside. Choosing the right box size helps prevent water bottles from shifting around during transit, reducing the risk of damage. A well-sized box also helps minimize the use of excessive packaging materials, which can increase costs and contribute to waste.

Ensure that the box has enough space to accommodate both the bottles and the protective materials like foam or bubble wrap, but not so much extra space that the bottles move freely within the box. Custom-sized boxes or adjustable packaging can provide an ideal fit, especially for large wholesale orders.

Securing the Bottles Inside the Package

Once the bottles are cushioned with the appropriate materials, securing them inside the box is essential to prevent movement. Stretch wrap or shrink wrap can be used to bundle the bottles together, keeping them aligned and preventing them from moving around. This is particularly useful for smaller orders or when multiple bottles are being shipped together.

For bulk shipments, you can also use corrugated trays or cardboard inserts that hold the bottles in place. These materials are both affordable and effective at preventing movement and reducing the likelihood of product damage.

Layering and Weight Distribution

In cases where you are shipping large quantities of water bottles, layering the bottles in the box can add extra protection. Place a layer of padding (such as foam or bubble wrap) at the bottom of the box, followed by a layer of bottles, then another layer of padding on top. By distributing the weight evenly throughout the package and ensuring that each bottle is cushioned on all sides, you reduce the likelihood of pressure damage during shipping.

When packing boxes, it’s important to avoid overpacking or underpacking. If the box is too full, the bottles may be crushed or damaged. If it is underpacked, the bottles may move around too much, leading to shifting and breakage. Proper weight distribution is crucial for ensuring the safety and integrity of the bottles during transit.

Cost-Effective Packaging Solutions for Wholesale Orders

Using Bulk Packaging Materials

When dealing with wholesale orders, the goal is to minimize costs while ensuring product safety. One effective way to reduce packaging costs is by using bulk packaging materials. Purchasing foam inserts, bubble wrap, or corrugated cardboard in bulk allows you to take advantage of economies of scale, lowering the cost per unit of packaging materials.

Buying materials in bulk not only saves money but also ensures consistency across orders, streamlining your packaging process. With standardized materials, you can quickly and efficiently pack large orders, reducing labor time and packaging errors.

Optimizing Shipping Boxes for Size and Weight

Shipping costs are directly tied to the size and weight of the package. To minimize shipping expenses, it’s important to optimize the size and weight of your boxes. Avoid using overly large boxes for small orders, as this increases the weight and volume, resulting in higher shipping costs. Similarly, use lightweight yet durable packaging materials to keep the overall weight of the package low without sacrificing protection.

Using flat-pack shipping boxes can also help reduce packaging material costs. These boxes are pre-scored, allowing you to fold and assemble them as needed, minimizing storage and shipping space. Additionally, foldable cardboard trays can be an effective, cost-efficient solution for organizing and stacking multiple bottles in a compact way.

Streamlining Packaging and Labor

Bulk water bottle orders often require significant packaging labor. To streamline the packaging process, consider using automated packaging solutions or implementing lean packaging practices to minimize waste. Automated wrapping and sealing machines can speed up the packing process, ensuring that each box is securely packed in less time.

Training your packaging staff to follow a standardized process for packing water bottles ensures consistency and reduces human error. For example, create a checklist that outlines the necessary steps: checking the condition of the bottles, using the right packing materials, securing the boxes, and labeling them correctly. Standardizing this workflow helps speed up production and maintain high-quality packaging standards.

Branding and Customization in Bulk Packaging

Custom Packaging for Brand Identity

In today’s competitive market, brand identity plays a crucial role in product differentiation. Custom packaging for wholesale orders offers an opportunity to showcase your brand and make a lasting impression on your customers. Branded packaging communicates professionalism and can help your products stand out from the competition.

Customizing shipping boxes with your logo, company colors, and unique designs can increase brand visibility, especially when the packages are handled by distributors, retailers, or customers. You can also consider custom labels or stickers to add additional brand messaging to the package.

Eco-Friendly Customization Options

For companies focused on sustainability, consider using eco-friendly packaging options for your custom branding. Instead of using conventional plastic tape or non-recyclable materials, opt for recycled cardboard or biodegradable packaging materials. Custom printed kraft paper and water-based ink can offer a more sustainable approach to branding.

Eco-conscious consumers are increasingly concerned with the environmental impact of packaging, so demonstrating your commitment to sustainability through eco-friendly packaging can help enhance your brand’s reputation.

Product Inserts and Additional Branding Opportunities

In addition to custom boxes and labels, consider including product inserts or promotional materials inside the package. These inserts can include thank-you notes, product care instructions, or promotional flyers that encourage customers to purchase again or explore other products. Offering exclusive discounts or cross-promotions with other products can help build customer loyalty and encourage repeat business.

Inserts are also a great opportunity for educating customers about your company’s environmental initiatives or how to properly reuse or recycle the water bottles. For example, if your company sells sustainable water bottles, the insert could include tips on reducing plastic waste or how to recycle the packaging after the bottles have been opened.

Environmental Impact and Sustainability in Bulk Packaging

Reducing Packaging Waste

As consumer demand for sustainable products grows, so does the pressure on businesses to reduce packaging waste. In the wholesale water bottle sector, this means opting for minimalist packaging that eliminates unnecessary materials and focuses on providing adequate protection for the bottles without excess waste.

Consider using single-material packaging (such as corrugated cardboard or biodegradable packing peanuts) that can easily be recycled. Avoid using multiple layers of packaging or combining materials that are difficult to separate for recycling, such as plastic and paper.

Recycled and Recyclable Packaging Materials

One of the most effective ways to reduce the environmental impact of your packaging is by using recycled and recyclable materials. Cardboard, paper, and certain plastics can be recycled after use, helping to keep waste out of landfills. Many packaging suppliers offer sustainable alternatives to conventional packing materials, so you can choose options that align with your brand’s environmental goals.

Another approach is to encourage customer recycling by providing clear instructions on how to properly dispose of or recycle the packaging materials. Including a note inside the package that reminds customers to recycle or reuse the packing materials helps raise awareness and promotes sustainability.

Eco-Friendly Packaging Innovations

The packaging industry is rapidly evolving with new innovations aimed at reducing waste and increasing sustainability. Consider exploring emerging technologies like plant-based plastics or compostable packaging materials that can help minimize the carbon footprint of your water bottle packaging.

Additionally, incorporating refillable or reusable packaging—such as shipping bottles or crates that customers can return for reuse—can significantly reduce the need for new packaging altogether, cutting waste and reinforcing your commitment to sustainability.

Optimizing Logistics and Distribution for Wholesale Orders

Efficient Packaging for Bulk Distribution

When packaging for wholesale distribution, it’s important to consider the logistics of the entire process. Shipping large volumes of water bottles can be complex, but with careful planning, you can reduce costs and improve efficiency. Streamline the packing process by batching similar orders together, ensuring that each box is filled to its optimal weight and size to minimize shipping fees.

Optimize your inventory management system to ensure that you have the right packaging materials on hand when large orders are placed. Having a clear, organized process for packaging and shipping will help ensure that orders are fulfilled on time, keeping both your customers and your bottom line satisfied.

Partnering with Logistics Providers

Choosing the right logistics partners is key to ensuring smooth delivery of wholesale orders. Work with reliable shipping companies that can handle large volumes and offer affordable rates for bulk shipments. Consider negotiating bulk shipping discounts or contract rates with logistics providers to lower costs and improve delivery times.